- 8 May 2023

- 118

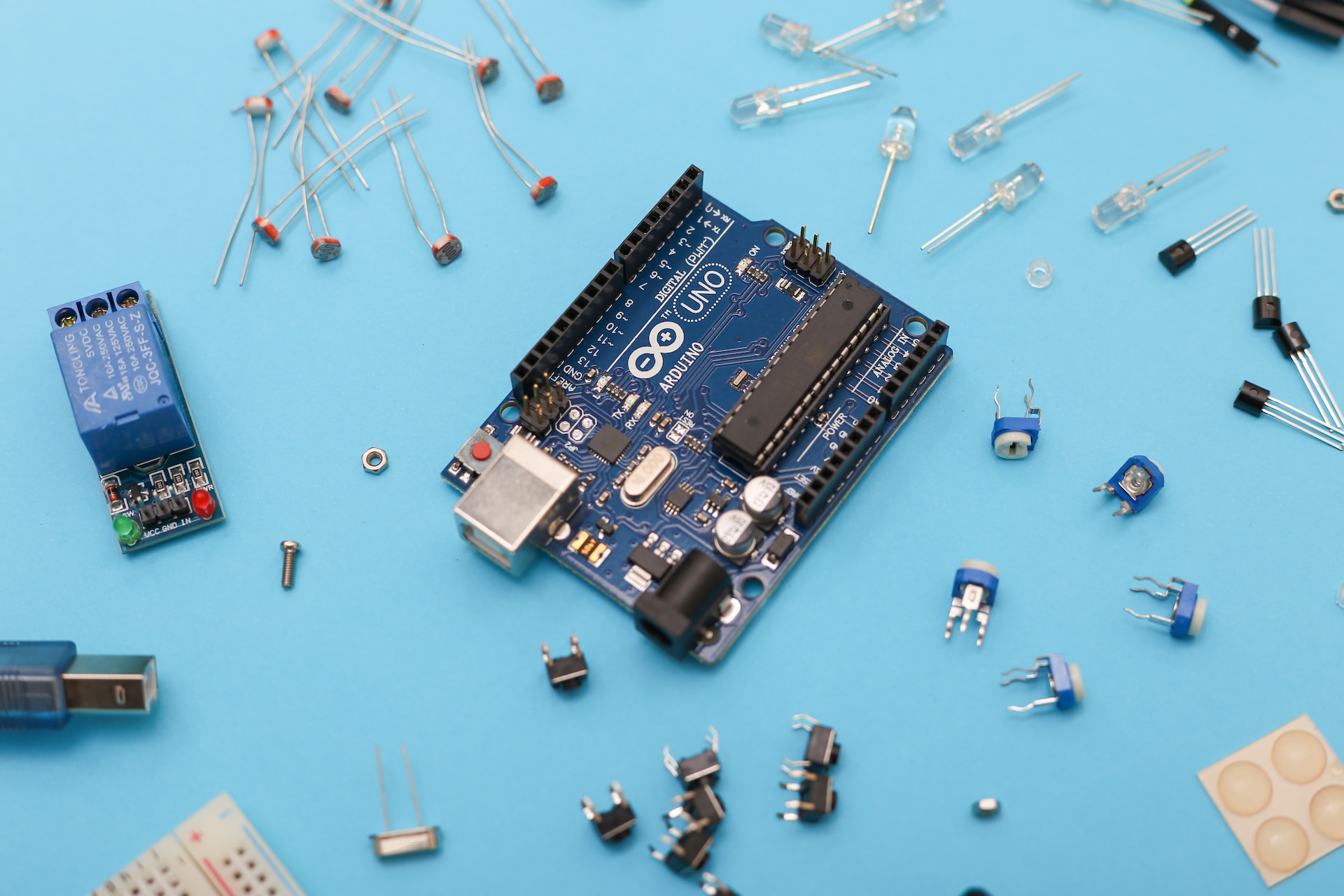

Automotive industry grapples with unprecedented microchip shortage

The global automotive industry is facing an unprecedented shortage of semiconductors, also known as microchips, which are essential components in the production of modern vehicles. The shortage has disrupted production lines and resulted in reduced output, leading to longer wait times for consumers who are looking to purchase new cars.

The shortage has been attributed to a number of factors, including the COVID-19 pandemic, which caused a surge in demand for electronic devices as more people shifted to remote work and online learning. This surge in demand has put pressure on semiconductor manufacturers, who have struggled to keep up with the pace of production.

In addition, the pandemic has led to factory shutdowns and shipping delays, further exacerbating the shortage. The situation has been compounded by a fire at a major semiconductor plant in Japan and severe winter storms in Texas, which disrupted production and transportation.

The microchip shortage has hit automakers hard, with many forced to shut down production lines and furlough workers. The shortage is particularly acute for automakers that rely heavily on semiconductors for advanced driver assistance systems (ADAS) and other safety features, as well as for electric vehicles, which require more complex and specialized chips.

The shortage is also affecting the used car market, as dealerships are finding it difficult to source replacement parts and are therefore holding onto older vehicles for longer periods of time.

Automakers are scrambling to find solutions to the problem, with some resorting to purchasing chips on the open market at inflated prices or negotiating directly with suppliers to secure their supply. Others are looking to diversify their supply chains to reduce their reliance on a single supplier or region.

Some industry experts believe that the shortage could continue well into 2022 and possibly beyond, as the semiconductor industry struggles to ramp up production to meet demand. The situation is causing uncertainty for automakers and consumers alike, as it is unclear when production will return to normal levels and when consumers will be able to purchase new cars without significant wait times.

The microchip shortage is a stark reminder of the complex and interconnected nature of the global supply chain and the challenges that can arise when disruptions occur. It highlights the need for greater resilience and flexibility in supply chains, as well as the importance of investing in new technologies and processes to mitigate future risks.

In the short term, the shortage is likely to result in increased prices for new and used cars, as well as longer wait times for consumers. However, in the long term, it could spur innovation and investment in new technologies, as automakers seek to reduce their reliance on semiconductors and develop more resilient supply chains.

Overall, the microchip shortage is a significant challenge for the automotive industry, but it also presents an opportunity for innovation and growth. As automakers adapt to the new reality of a disrupted supply chain, they will need to be agile, creative, and forward-thinking in order to thrive in a rapidly changing market.