- 8 May 2023

- 67

The ripple effects of the microchip shortage on the automotive industry

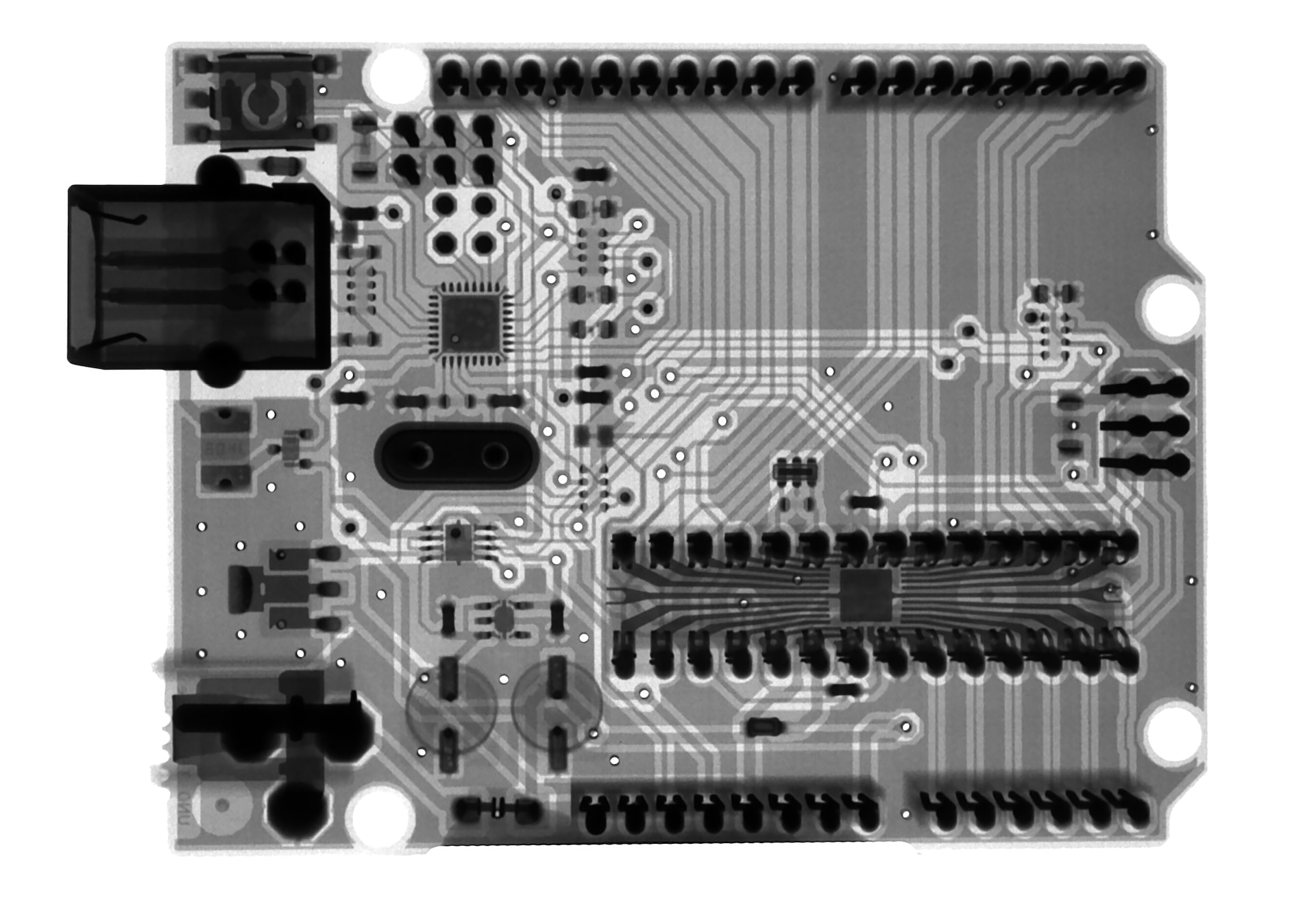

The global automotive industry has been facing an unprecedented challenge in recent months, as a shortage of microchips threatens to disrupt production and supply chains. The shortage has been caused by a combination of factors, including increased demand for consumer electronics during the COVID-19 pandemic, factory closures, and supply chain disruptions.

As the shortage continues, automakers have been forced to cut production, adjust their product mix, and even temporarily shutter factories. The effects of the shortage are being felt across the industry, from large multinational corporations to smaller component suppliers.

The ripple effects of the microchip shortage are far-reaching, and are expected to impact the industry for months, if not years, to come.

Production Disruptions

The microchip shortage has had a significant impact on the production of new vehicles. Many automakers have been forced to slow or halt production at their factories as a result of the shortage. This has resulted in lower inventory levels, longer wait times for customers, and reduced revenue for the automakers.

In some cases, automakers have been forced to prioritize production of their most profitable vehicles, such as trucks and SUVs, over lower-margin cars. This has led to a shift in product mix, as automakers attempt to maximize their profits in the face of the shortage.

Supply Chain Disruptions

The microchip shortage has also had an impact on the automotive supply chain. Many component suppliers rely on microchips to manufacture their products, and the shortage has led to delays and disruptions in the supply chain.

In some cases, suppliers have been forced to halt production of certain components, leading to further production disruptions at the automakers. This has created a ripple effect throughout the industry, as suppliers and automakers struggle to adapt to the changing landscape.

Pricing and Profitability

The microchip shortage has also had an impact on pricing and profitability within the automotive industry. As automakers adjust their product mix and prioritize production of higher-margin vehicles, prices for those vehicles are likely to increase.

This could lead to a shift in consumer behavior, as buyers may opt for used vehicles or lower-priced models due to the increased cost of new vehicles. In addition, the reduced production and supply chain disruptions could lead to increased costs for automakers, further impacting their profitability.

Future Implications

The microchip shortage is expected to have long-term implications for the automotive industry. As automakers and suppliers struggle to adapt to the shortage, they may invest in new technologies and manufacturing processes to reduce their reliance on microchips.

This could lead to a shift in the way vehicles are manufactured and designed, with a greater emphasis on electrification and automation. In addition, the shortage may lead to increased cooperation and collaboration within the industry, as companies work together to mitigate the impact of future disruptions.

Conclusion

The microchip shortage has had a significant impact on the automotive industry, disrupting production, supply chains, pricing, and profitability. While the industry is expected to recover in the coming months and years, the long-term implications of the shortage remain uncertain.

As the industry continues to grapple with the shortage, it is clear that greater cooperation and collaboration will be necessary to mitigate the impact of future disruptions. The automotive industry is a key driver of the global economy, and its ability to adapt and innovate in the face of challenges will be critical to its long-term success.